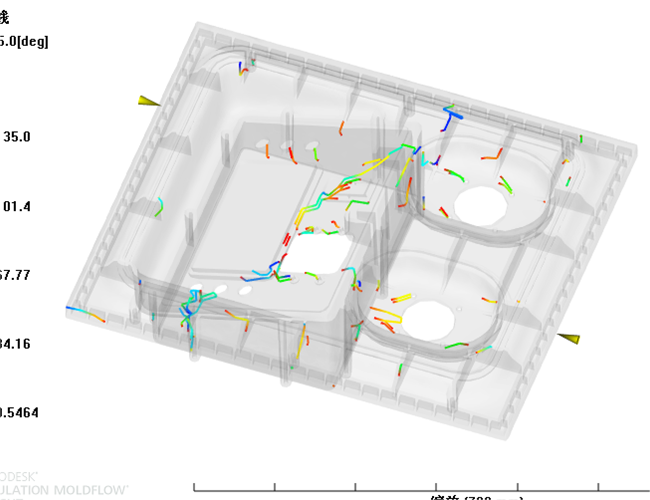

Engineering is what we do. We are a company for Product Engineering, Mold Design and Moldflow

LEARN MORE →

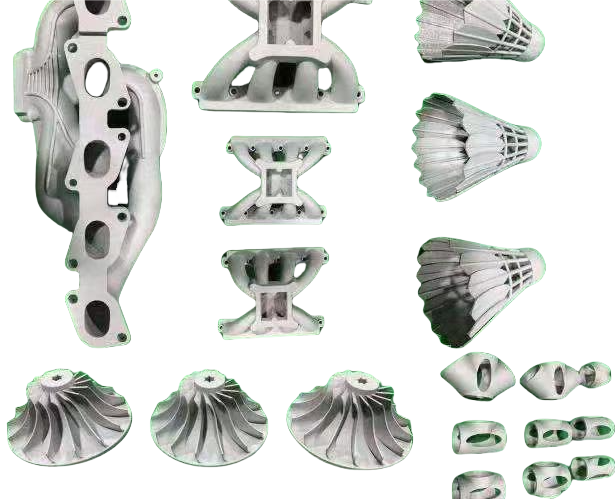

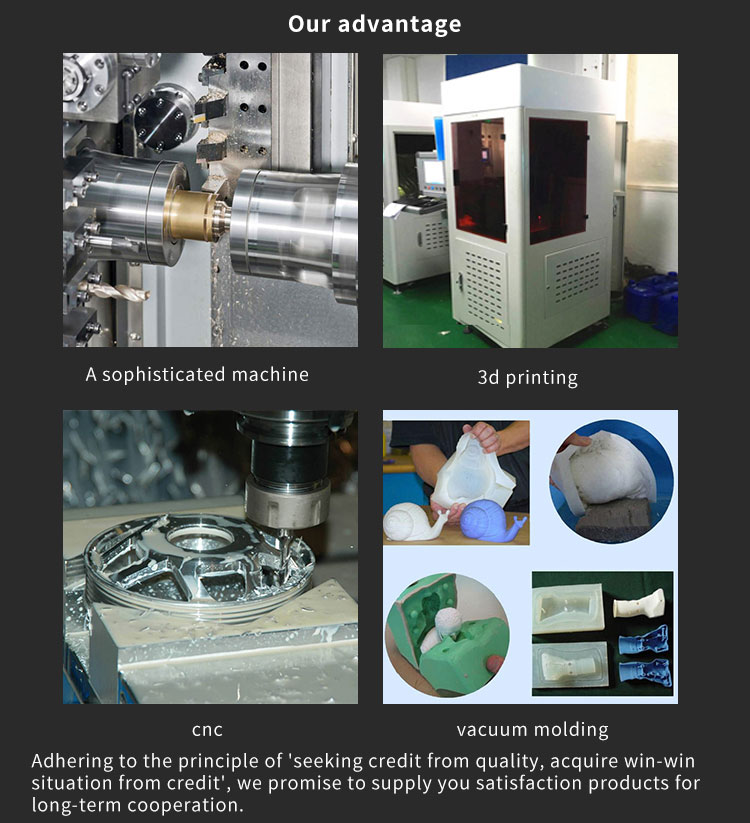

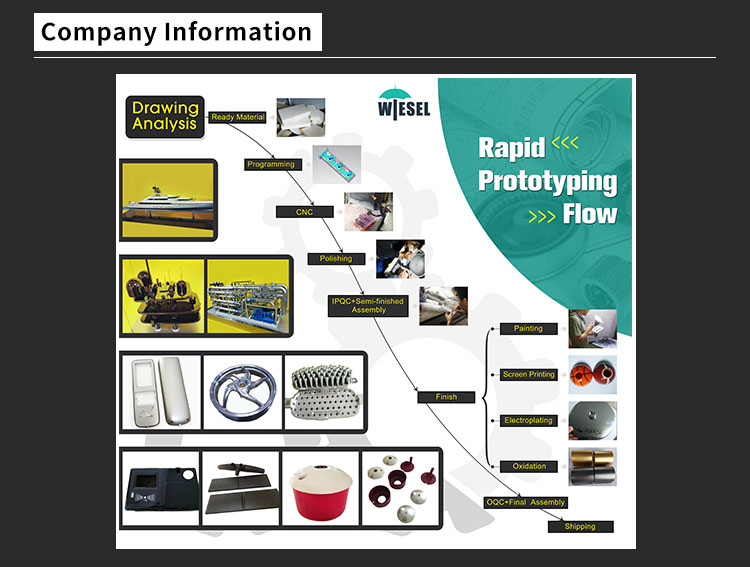

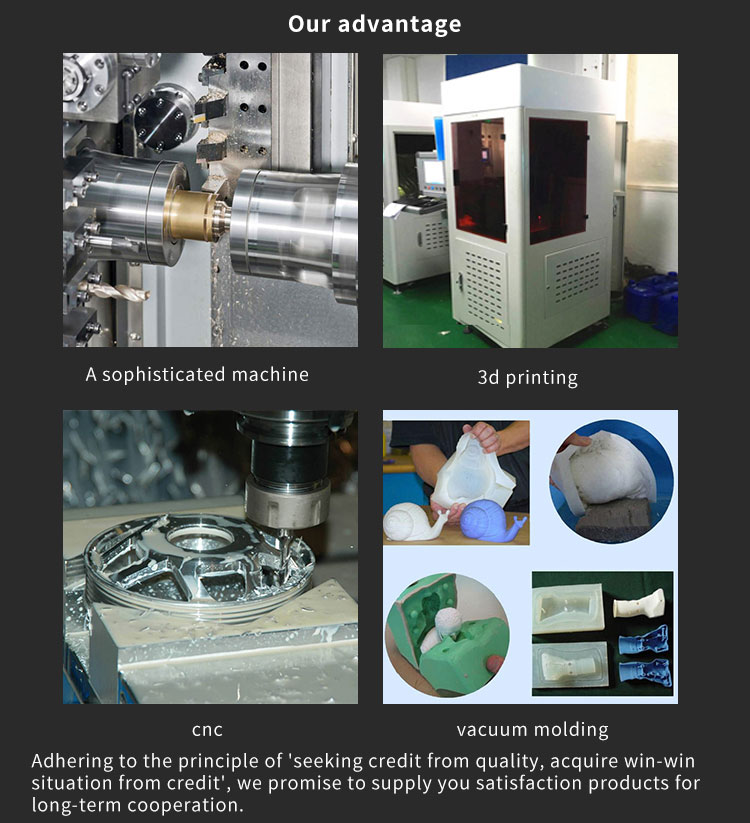

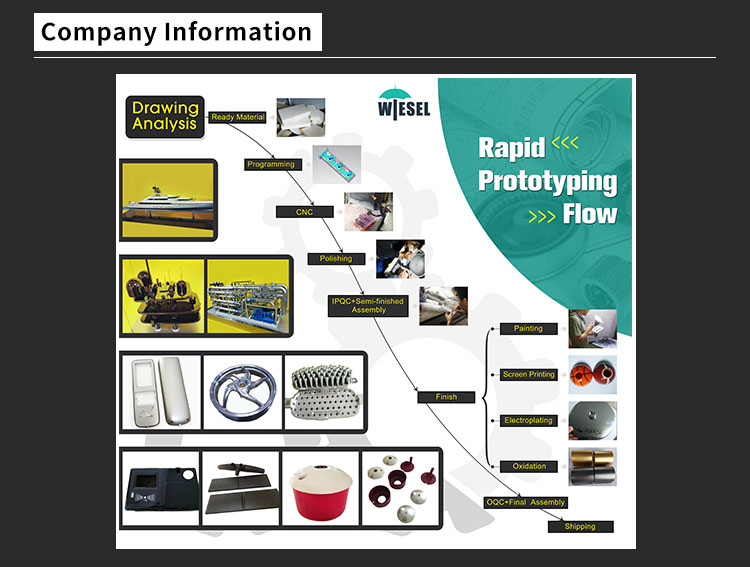

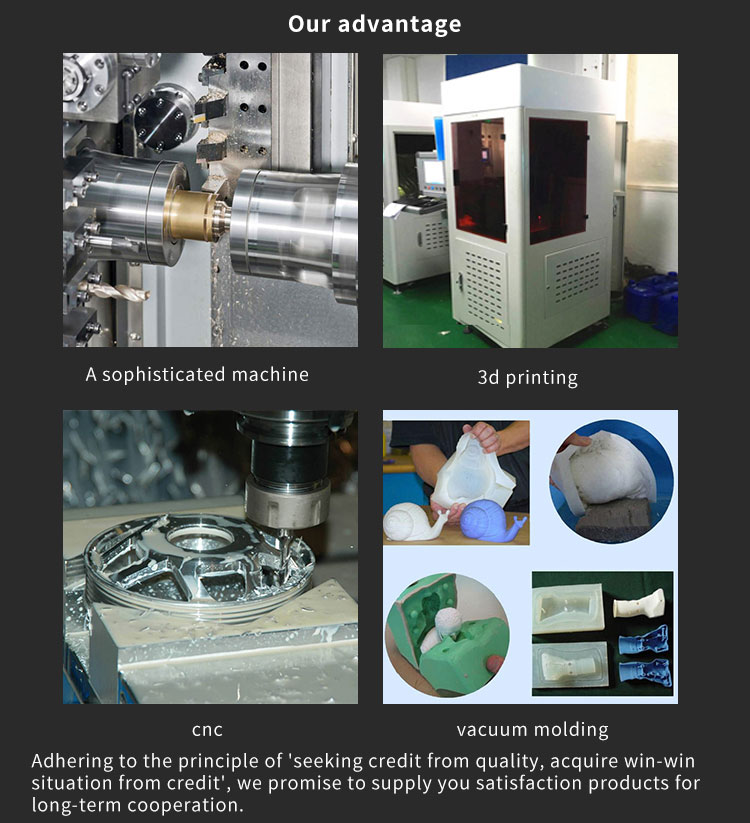

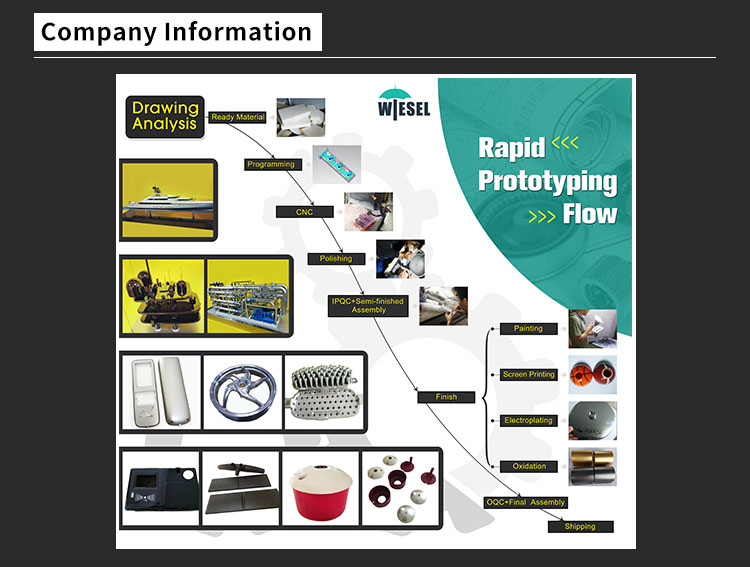

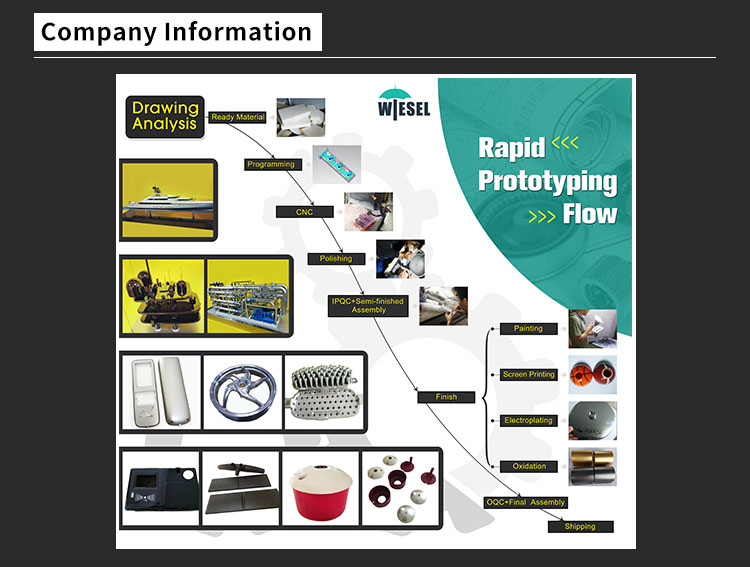

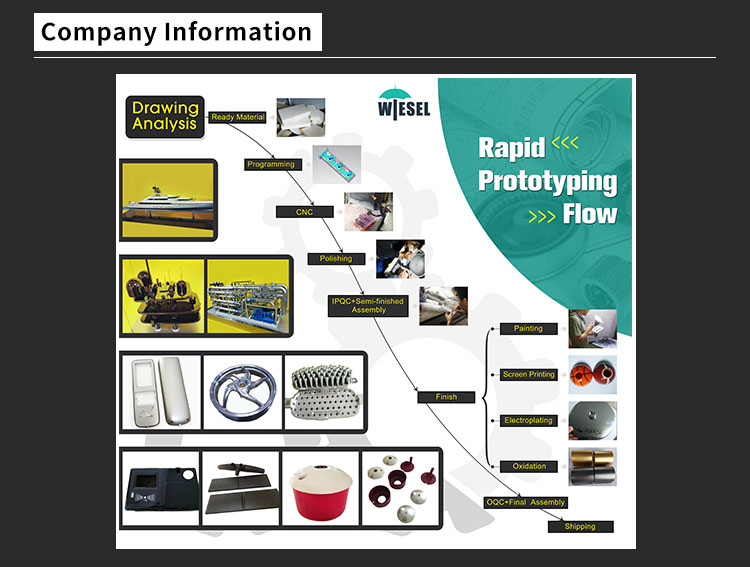

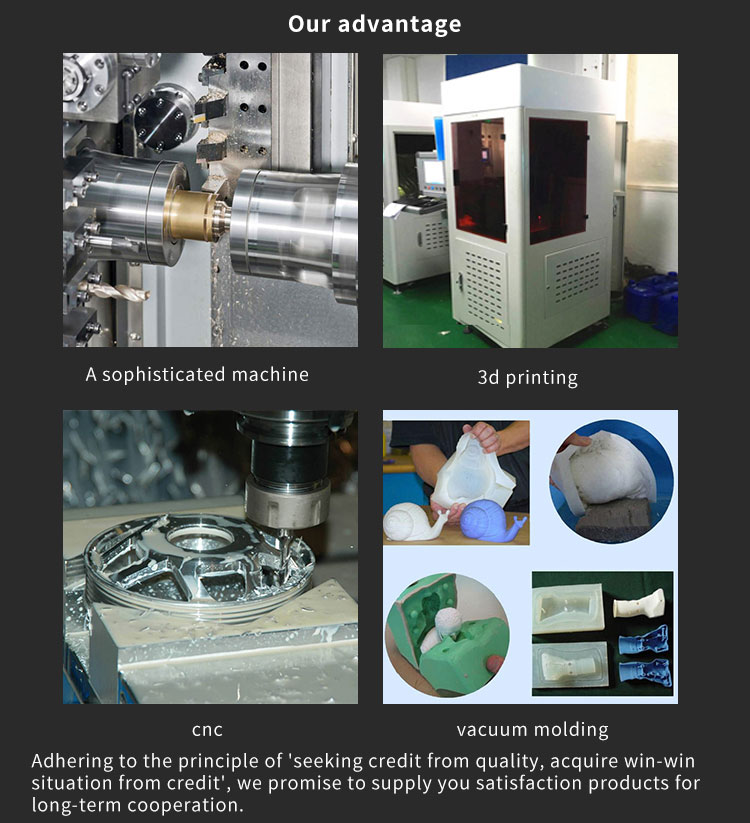

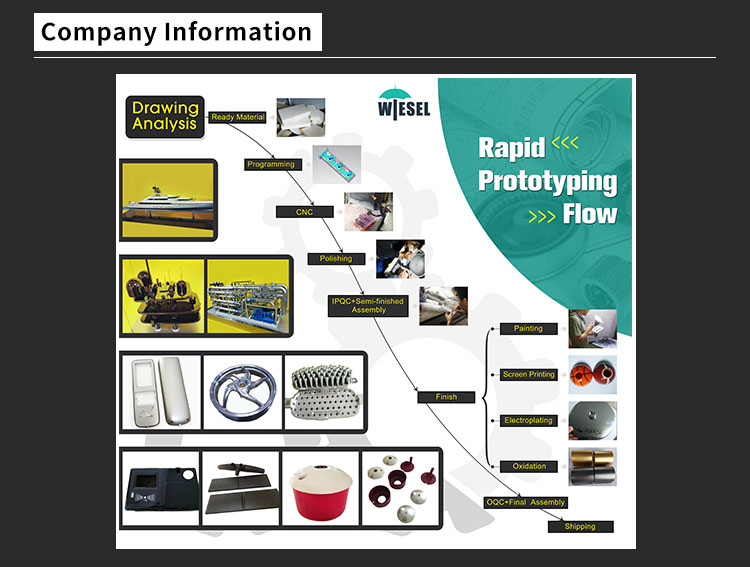

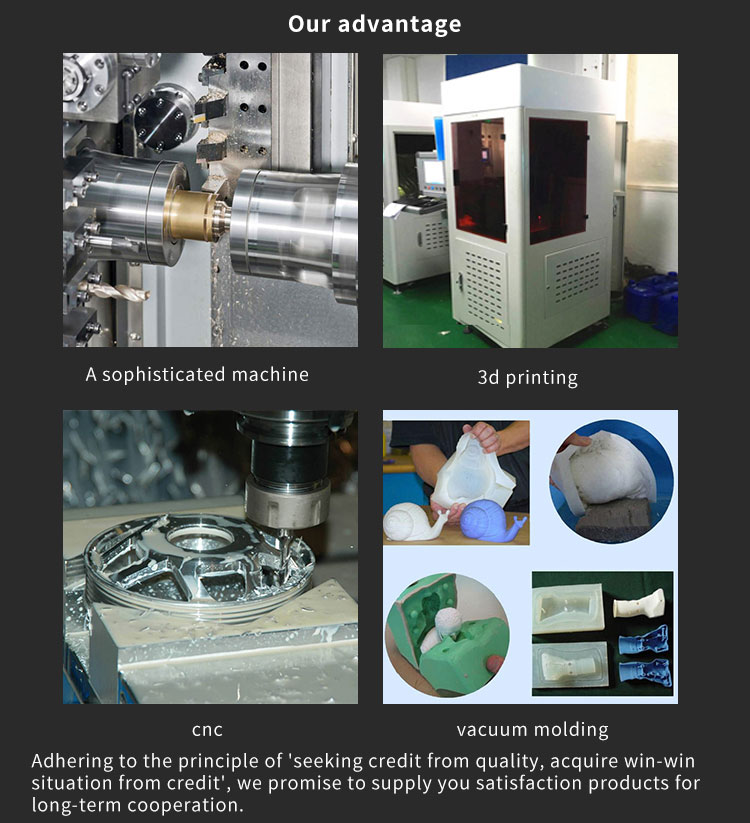

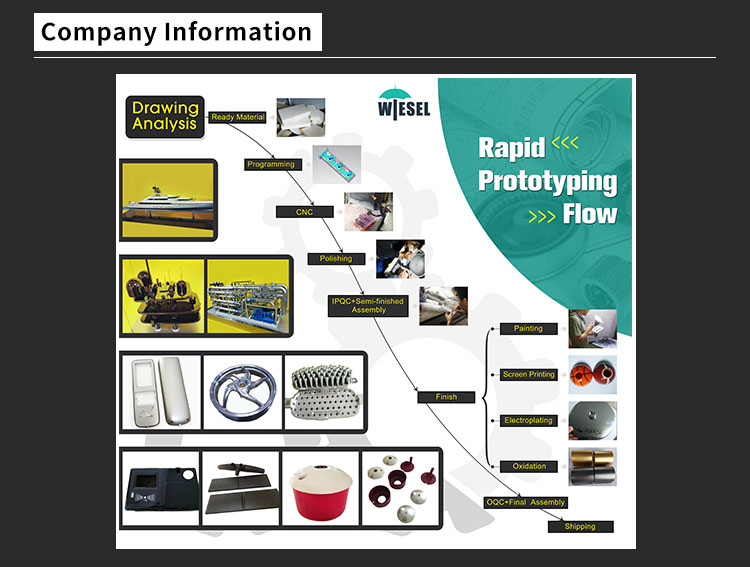

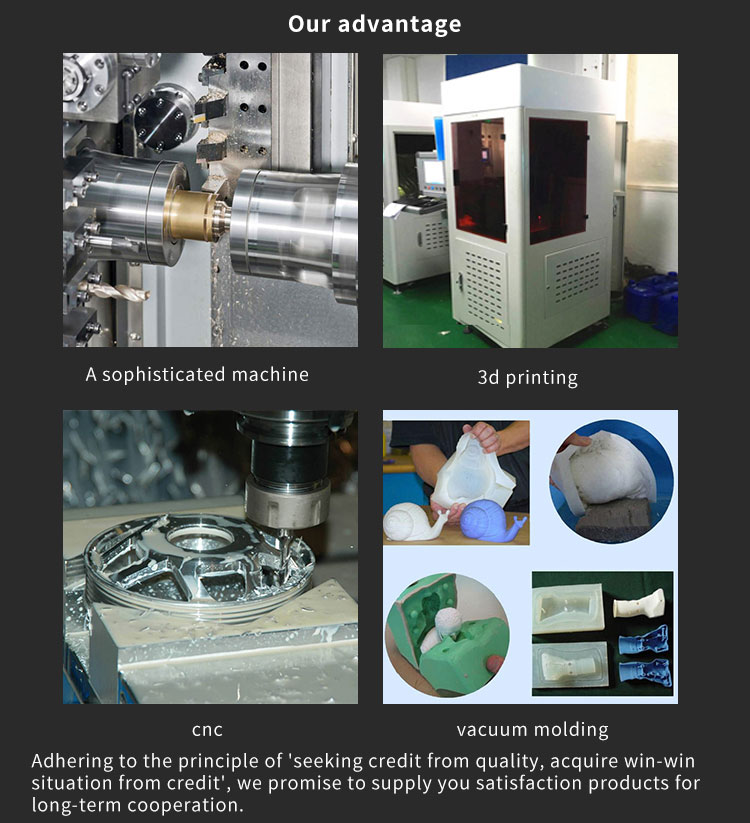

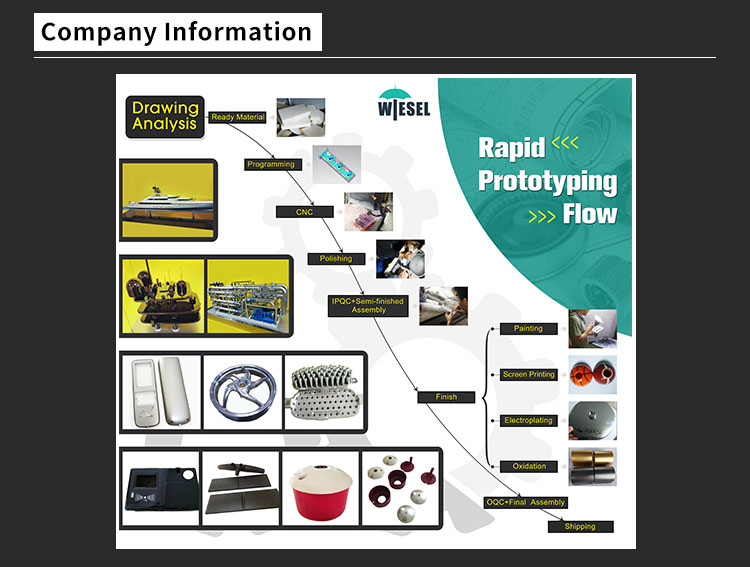

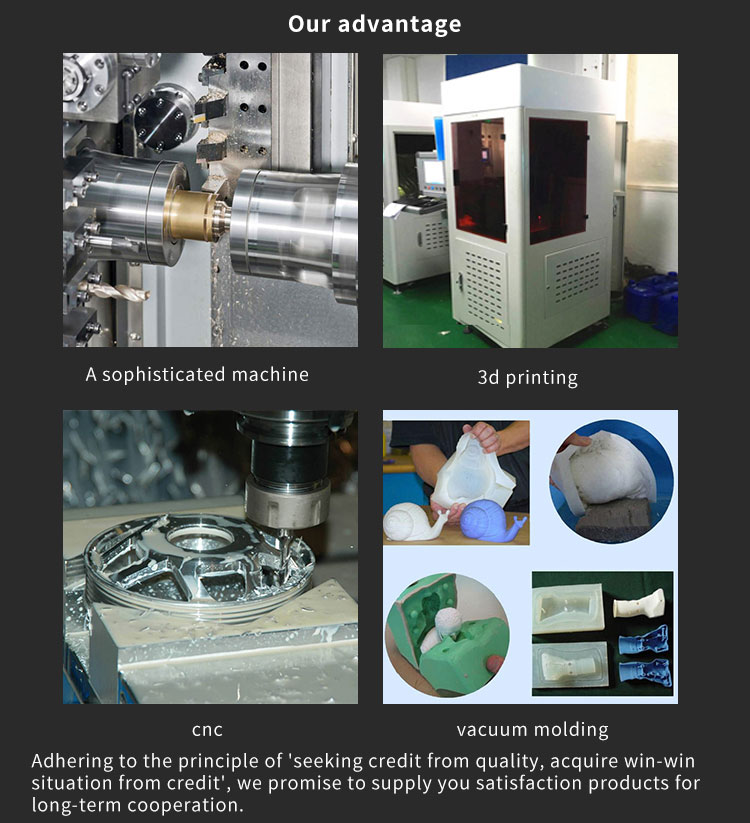

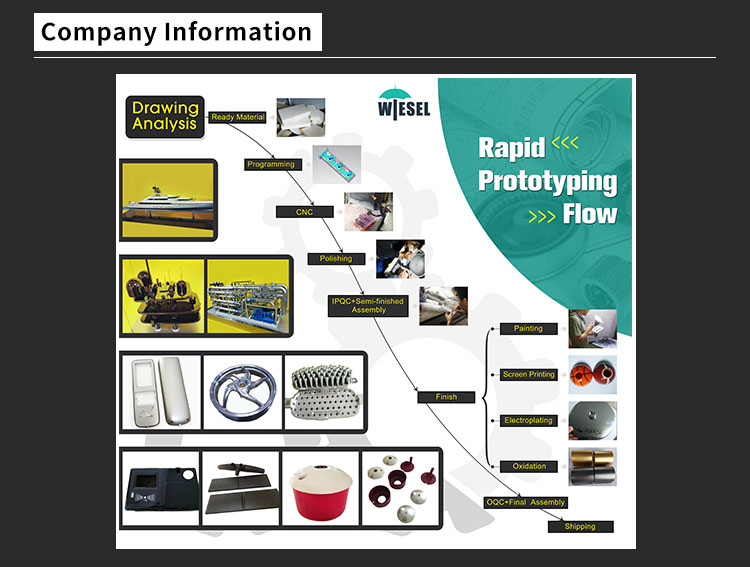

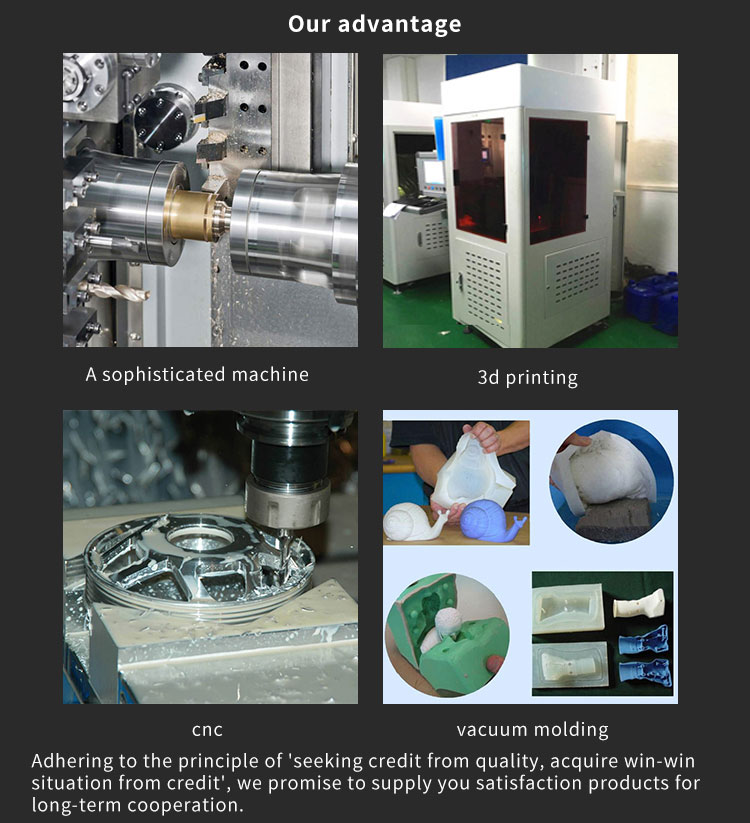

Way of Rapid Prototype inlcude Metal CNC, Plastic CNC, Vacuum molding, 3D printing.

LEARN MORE →

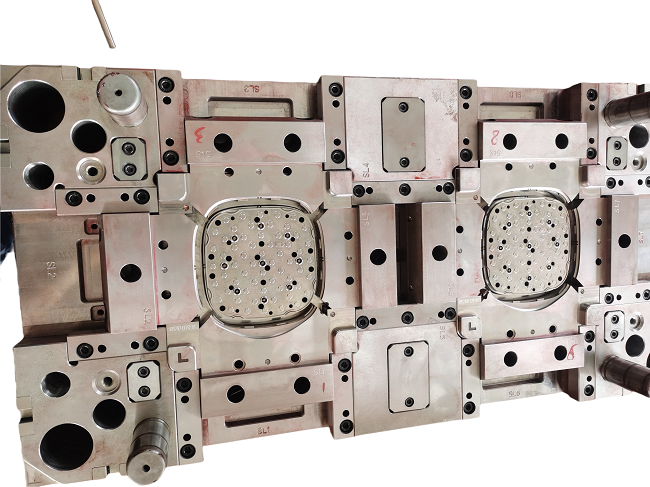

Mold Innovation for Injection Mold, Stamping Mold, Die Casting Mod and Custom other Mold

LEARN MORE →

Production For Plastic and Metal, Including Injection Molding, Die Casting Molding, Stamping Molding

LEARN MORE →

Product Finishing:Spray Printing, Electroplating, Power Coating

LEARN MORE →

Use many ways to control the quality of each part and Each Step

Multi layer quality control ensures 99.99% quality

Multi layer quality control ensures 99.99% quality

Multi layer quality control ensures 99.99% quality

Multi layer quality control ensures 99.99% quality

One Easy-To-Use Platform From Quote to Delivery

Xiamen Wiesel technology mainly provides metal 3D printing,plastic CNC,sheet metal fabrication,metal CNC,stamping mold,plastic mold,plsatic 3D printing,plastic rapid prototype,PMMA/PC_CNC,die casting mlding,automotive plastic injection mold, etc., which can be used in Musical instruments ,Agriculture ,Packaging ,Metalworking ,Automotive,Industrial manufacturing,Furniture ,Renewable energy ,Solar energy and other industries. It is equipped with advanced software that allows for precise control of cutting tools, resulting in consistent and uniform production. This method provides excellent repeatability, ensuring every part is identical and meets the required specifications.

| Product Name | automotive plastic injection mold |

| Brand Name | Wiesel |

| OEM/ODM | Acceptatble |

| Place of Origin | Xiamen,Fujian,China |

| Condition | New |

| Application | Agriculture ,Mining ...etc |

| Export countries | Indonesia,Peru,Chile...etc |

| Export region | Oceania,Southeast Asia,North America,Middle East... |

| Design | advanced |

| Material Capabilities | Hardened Metals,Brass,Precious Metals,Aluminum... |

| Type | mold/cnc |

| Loading port | xiamen |

| Warranty | 12 months |

| Color | Customized |

| Surface treatment | Color Anodize,Electroplating,Zink Plating,Sandblasting... |

| Packaging Details | Carton |

| After sale service | Online support |

| Lead time (days) | 7-30 (To be negotiated) |

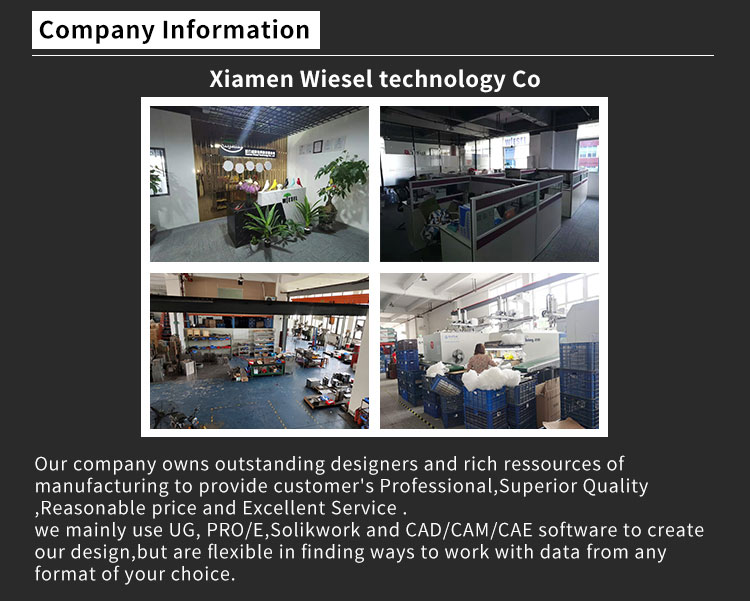

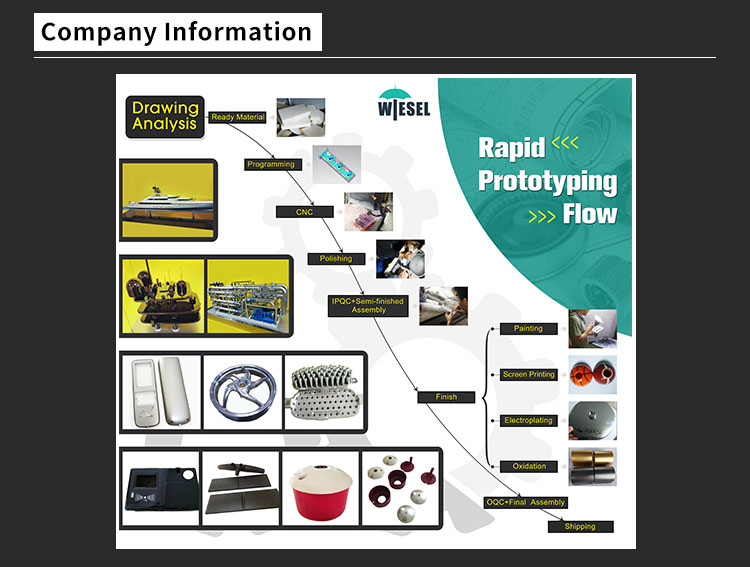

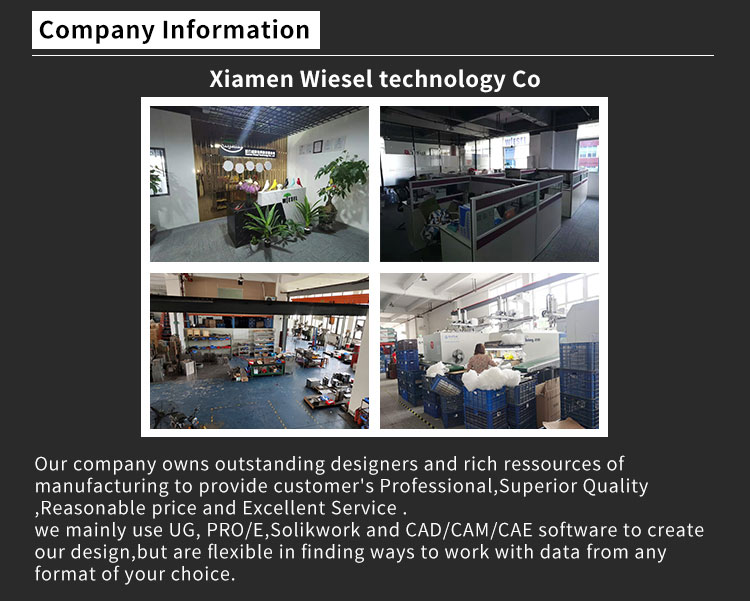

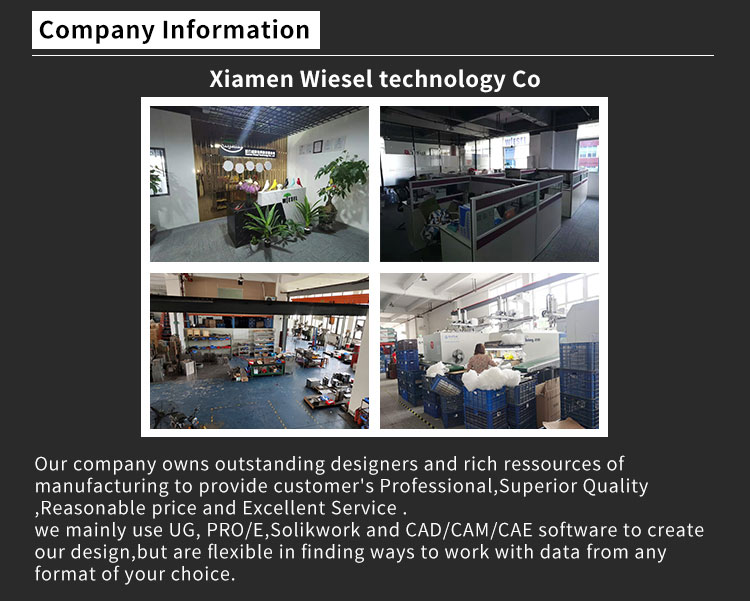

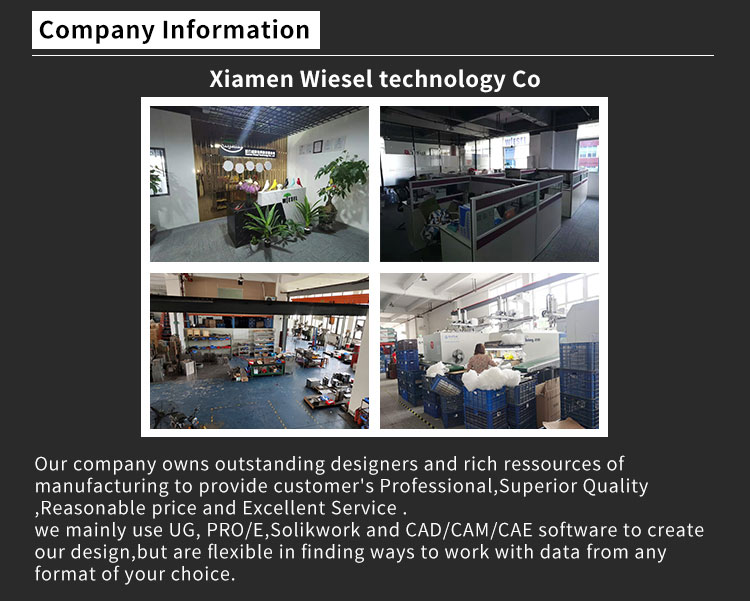

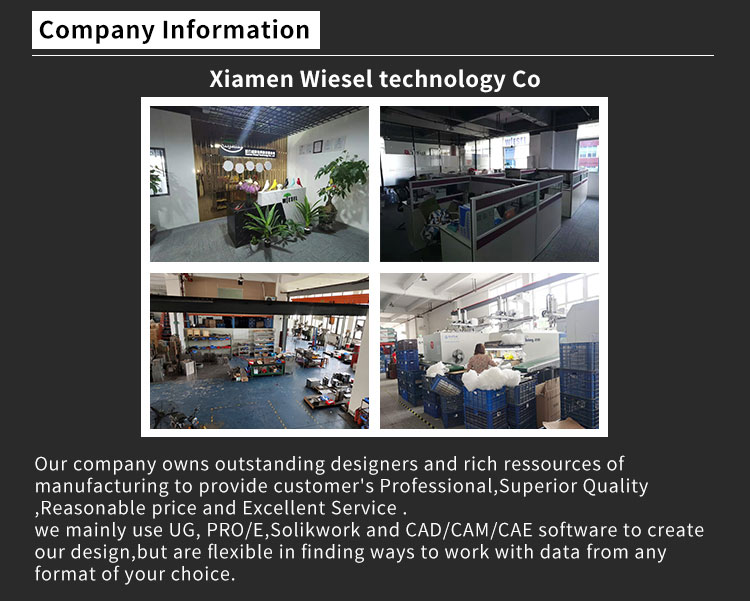

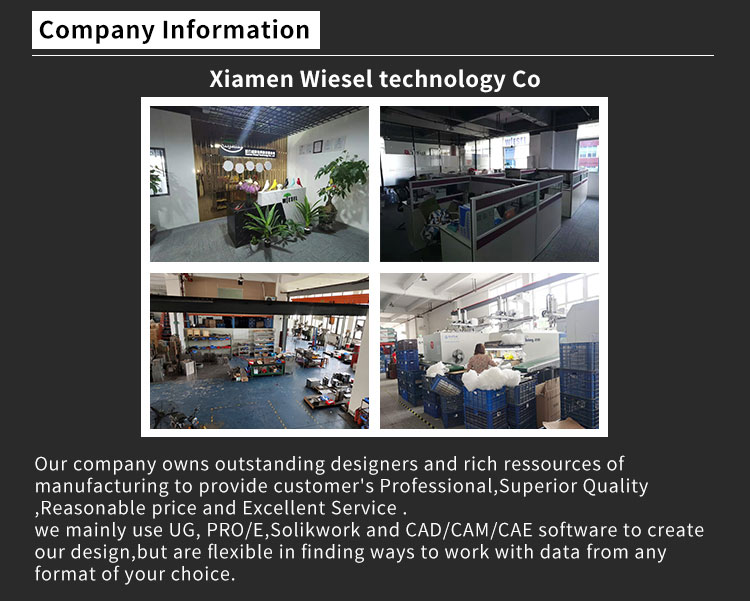

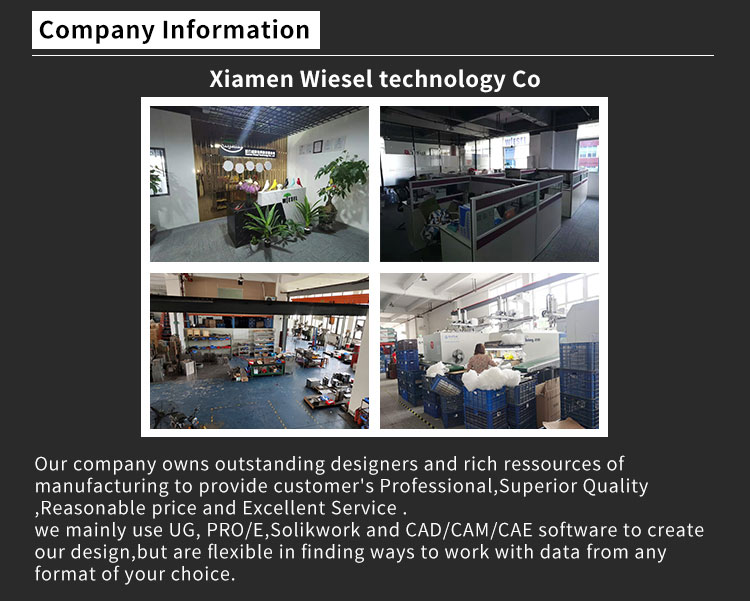

Our company information

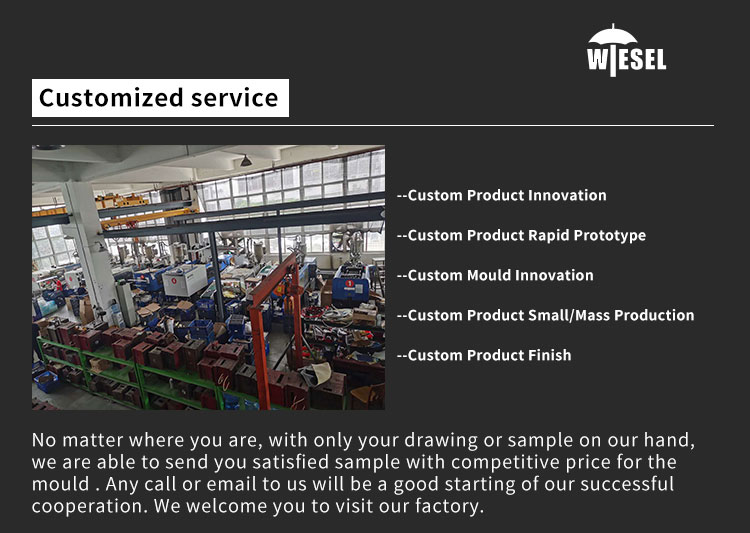

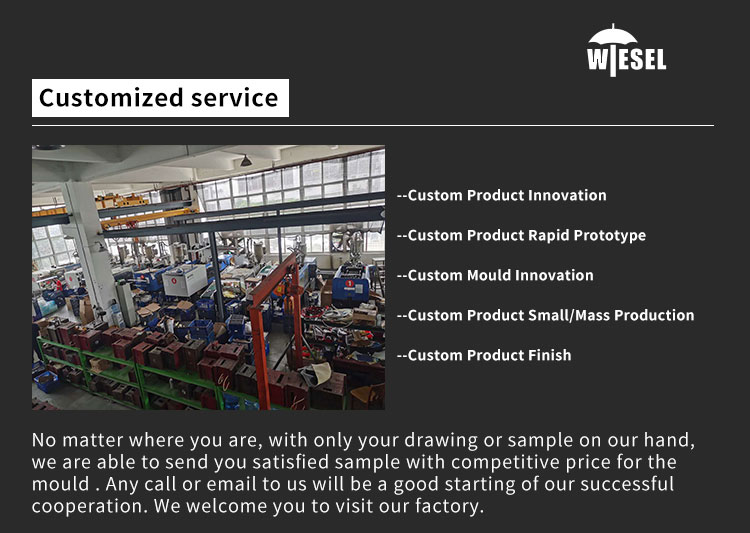

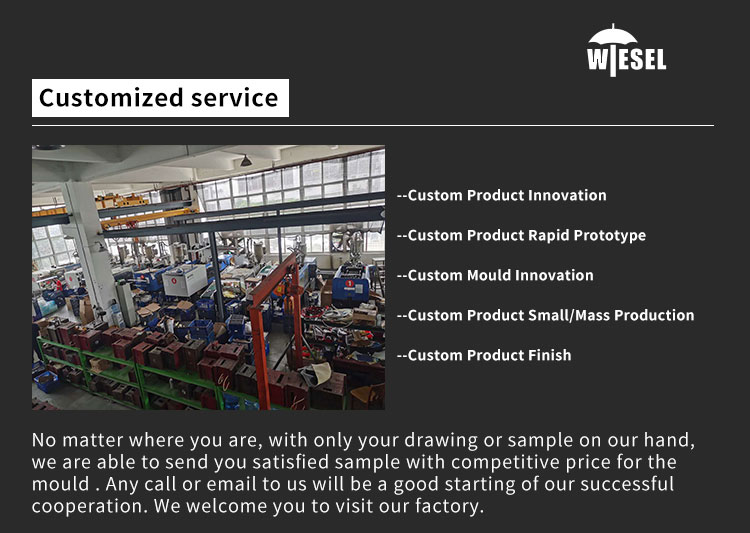

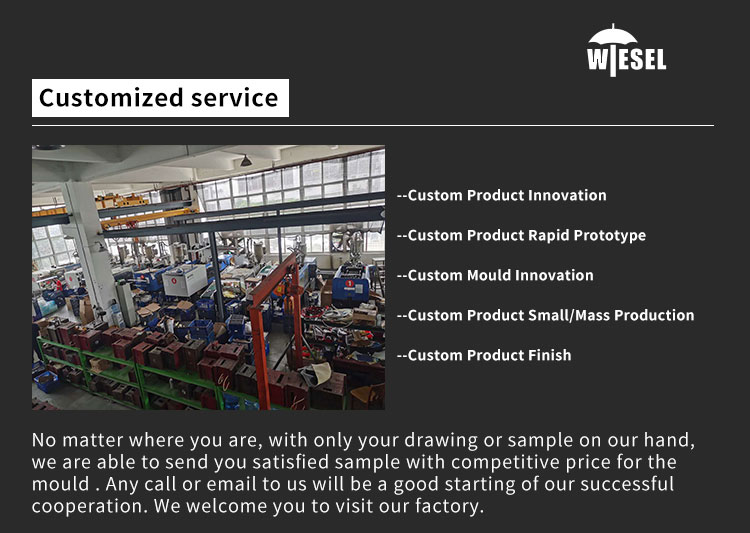

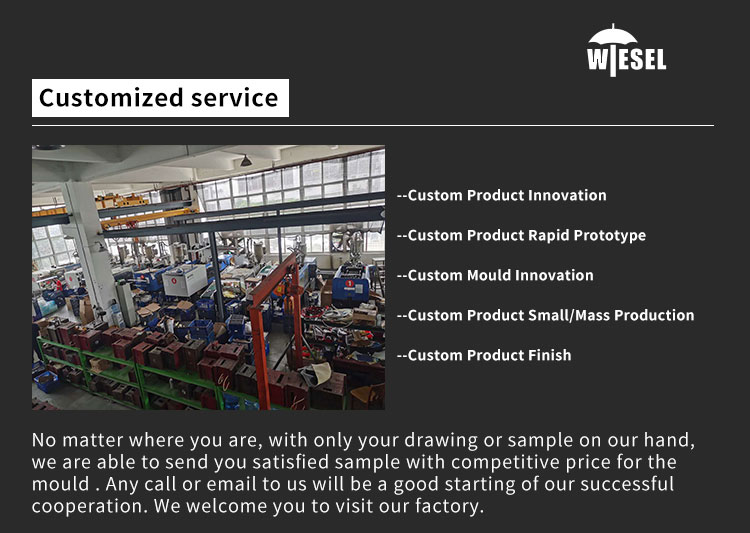

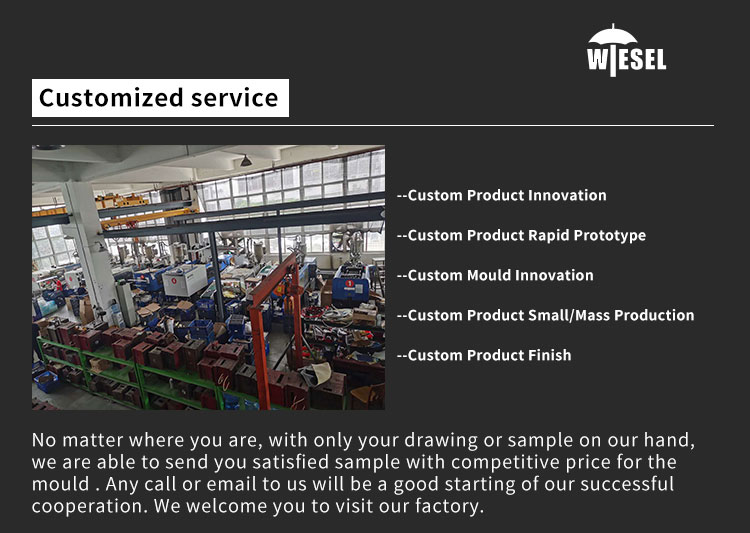

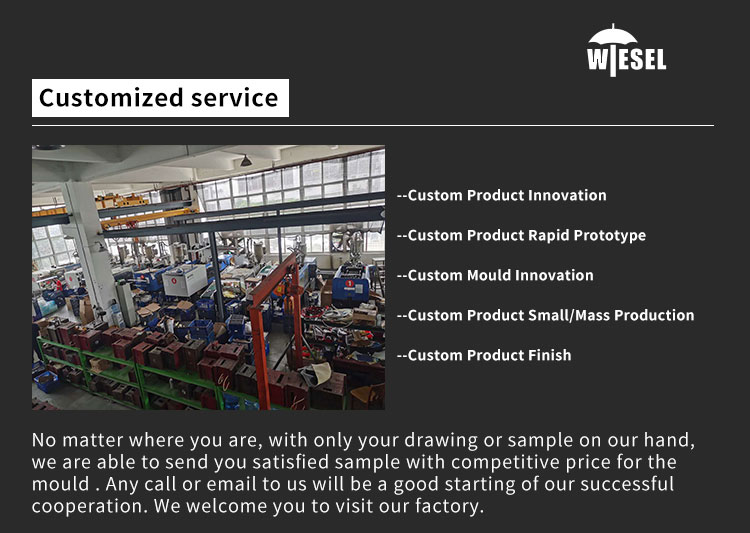

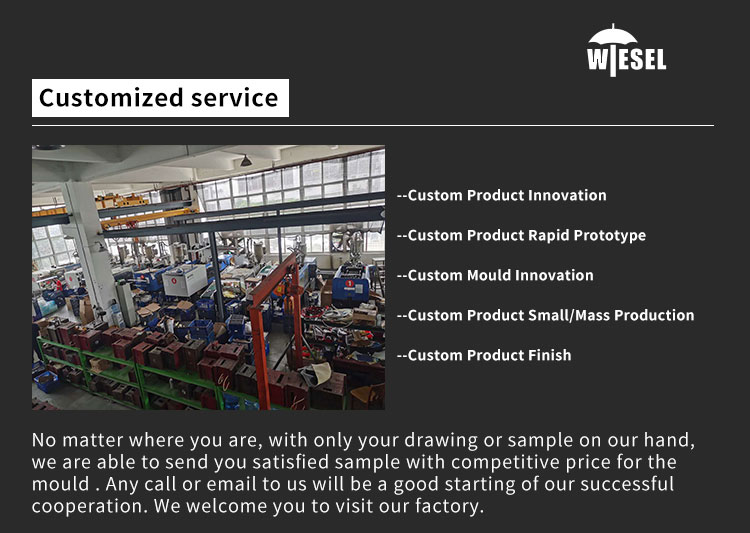

customized service

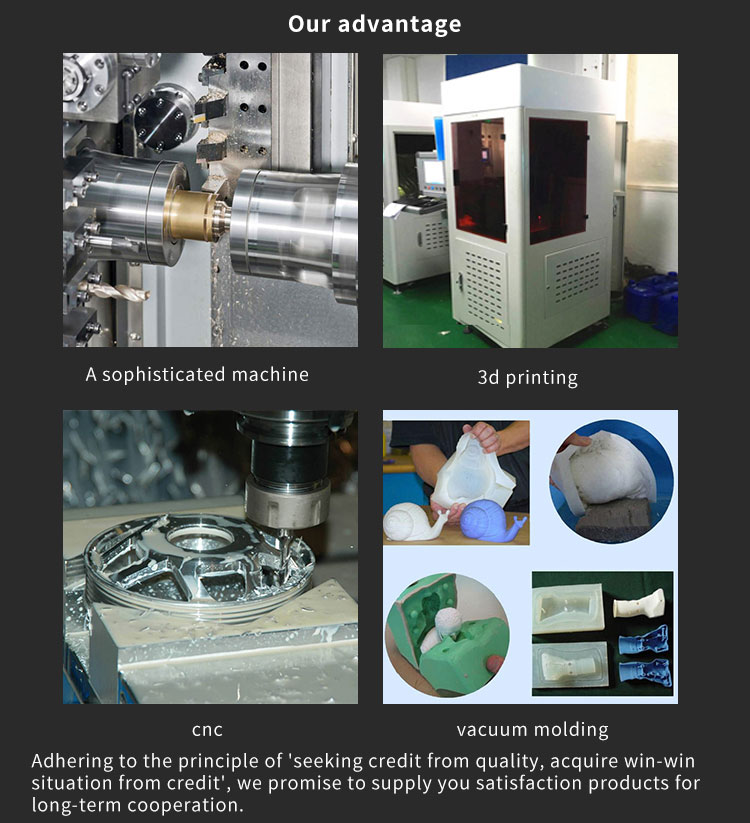

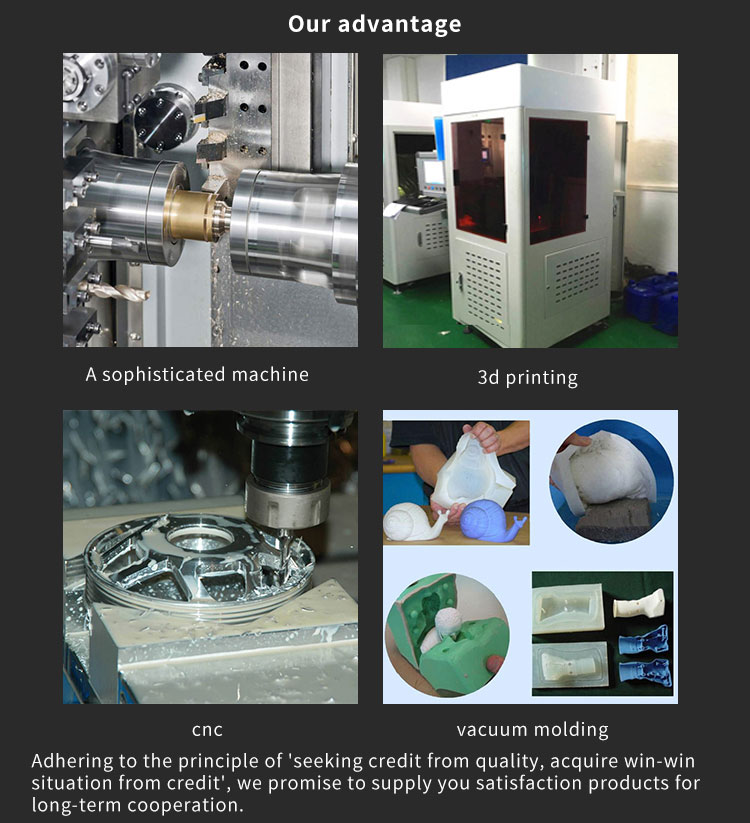

Our advantage

The packaging&shipping for automotive plastic injection mold

Xiamen Wiesel technology Co., Ltd focuses on the research and development of customized plastic molds, die-casting molds, and rapid prototyping. We have been committed to technology promotion, R&D team training, and new process development. The quality and life of the mold are highly guaranteed. With more than 10 years of experience in mold manufacturing, we have successfully developed a variety of products, including metal CNC,metal 3D printing,stamping mold,PMMA/PC_CNC,plastic injection moulding,plastic rapid prototype,plastic mold,plsatic 3D printing,sheet metal fabrication,plastic CNC,autodesk inventor mold design, etc. Our products are widely used and can be used in industries such as Oil and gas ,Mining ,Pharmaceutical ,Consumer goods ,Aerospace,Robotics ,Transportation , etc.

Our customers are almost all over the overseas market, including Pakistan,Indonesia,Peru,Korea,Russia,Kenya,Arabia,Senegal,Tokelau, and other countries and regions. No matter where you are, as long as we have your drawings or samples, we can send you satisfactory mold samples at a competitive price. We strictly control product quality and use instruments such as Tensioners,Height Gage,CALIPER,Coordinate Measure Machine,Torque sensors,Profile Projector for testing. We adhere to the principle of "quality for trust, trust for win-win", and promise to provide you with satisfactory products in order to cooperate for a long time. You are welcome to visit our factory.

| Name | autodesk inventor mold design |

| Brand Name | Wiesel |

| OEM/ODM | Support |

| Place of Origin | China |

| Condition | New |

| Export region | Southeast Asia,North America,Middle East,South America... |

| Style | Modern |

| Certificate | ISO9001 |

| Processing Type | CNC milling,CNC lathe machining,CNC grinding,CNC Machining... |

| MOQ | 100 Set |

| Warranty | 12 months |

| Color | Customized |

| Packaging Details | Standard |

| After sale service | Online support |

| Lead time (days) | 7-30 (To be negotiated) |

Our company information

customized service

Our advantage

The packaging&shipping for autodesk inventor mold design

Xiamen Wiesel technology Co., Ltd mainly provides stamping mold,metal 3D printing,plastic rapid prototype,PMMA/PC_CNC,sheet metal fabrication,metal CNC,plastic injection moulding,vacuum casting,plastic CNC,autocad mold design, etc., which can be used in Transportation ,Robotics ,Textile ,Consumer goods ,Home appliances ,Industrial manufacturing,Oil and gas ,Entertainment and other industries. The machining process begins by using CAD software to create a 3D model of the desired part. The model is then imported into CAM software, which generates tool paths and instructions for the CNC machine tool. Once the design and specifications are finalized, the metal pieces are mounted on the CNC machine and the cutting tools begin running.

| Name | autocad mold design |

| Place of Origin: | Xiamen,Fujian,China |

| Type: |

Broaching, DRILLING, Etching / Chemical Machining, Laser Machining, Milling, Other Machining Services, Turning, Wire EDM |

| CNC Machining or Not: | Cnc Machining |

| Available Materials: | Aluminum,Stainless steel,Hardened Metals... |

| Surface Treatment: | Color Anodize,Sandblasting,Powder Coating,Zink Plating... |

| OEM/ODM: | Support |

| Processing: | CNC Machining Service |

| Processing Level: | 3 4 5 6 Axis CNC TURNING MILLING |

| Item Name: | Accept Custom Logo |

| Quality Control: | 100% Inspection Before Shipment |

| Certification: | ISO 9001:2015 |

| Supply Ability: | 6193290 Piece/Pieces per Week as per customized |

| Quantity (pieces) | > 1716 |

| Lead time (days) | To be negotiated |

Our company information

customized service

Our advantage

The packaging&shipping for autocad mold design

They are equipped with specialized tools such as Tungsten carbide tool,Threading tool,Diamond cutting tool,Thread mill,Adjustable woodruff cutter,Facing tool,Countersink,Parting tool and grinders, which are programmed to rotate, rotate and move according to specifications set by the design software. This allows for precise shaping and cutting of different types of metals, including Cast iron,Bronze,Silicon,Carbon steel,Phosphorus bronze,Lead,Manganese,Nitinol,Brass alloy.

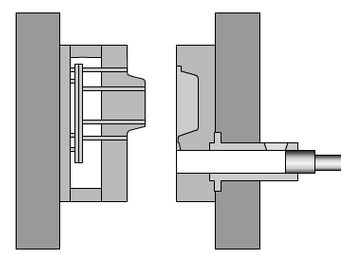

| Name | auto injection mold |

| Material Capabilities | Precious Metals,Aluminum,Copper,Hardened Metals... |

| Type | Laser Machining, Milling, Other Machining Services, Turning, Rapid Prototyping |

| Surface treatment | Zink Plating,Electroplating,Powder Coating,Color Anodize... |

| Tolerance | 0.007-0.01mm |

| Process | Cnc Machining + Surface Treatment |

| Equipment | Milling Machine :3/4/5 Axis CNC Machining Center:Turning Centre |

| Quality Control | ISO/TS9001 |

| Name | Custom Machining Metal Parts Service |

| Place of Origin | Xiamen,Fujian,China |

Our company information

customized service

Our advantage

The packaging&shipping for auto injection mold

Xiamen Wiesel technology Co., Ltd mainly provides metal CNC,sheet metal fabrication,plastic injection moulding,plastic mold,die casting mlding,PMMA/PC_CNC,metal 3D printing,vacuum casting,stamping mold,asm al-si alloys casts by die casting, etc., which can be used in Solar energy ,Defense ,Metalworking ,Education ,Food and beverage ,Electronics ,Aerospace,Medical and other industries. The machining process begins by using CAD software to create a 3D model of the desired part. The model is then imported into CAM software, which generates tool paths and instructions for the CNC machine tool. Once the design and specifications are finalized, the metal pieces are mounted on the CNC machine and the cutting tools begin running.

| Name | asm al-si alloys casts by die casting |

| Material Capabilities | Precious Metals,Stainless steel,Copper,Aluminum... |

| Type | Laser Machining, Milling, Other Machining Services, Turning, Rapid Prototyping |

| Surface treatment | Powder Coating,Zink Plating,Color Anodize,Electroplating... |

| Tolerance | 0.008-0.01mm |

| Process | Cnc Machining + Surface Treatment |

| Equipment | Milling Machine :3/4/5 Axis CNC Machining Center:Turning Centre |

| Quality Control | ISO/TS9001 |

| Name | Custom Machining Metal Parts Service |

| Place of Origin | China |

Our company information

customized service

Our advantage

The packaging&shipping for asm al-si alloys casts by die casting

It is controlled by a computer program that directs the machine's movement, speed and cutting depth to make precise and complex cuts in metal materials. Metal materials used in CNC machining range from Nickel,Titanium,Bronze,Carbon steel,Vanadium,Brass alloy,Bronze alloy,Zinc,Tungsten,Gold and other alloys. CNC machining is commonly used in various industries, including Food and beverage ,Defense ,Education ,Home appliances ,Automotive,Solar energy ,Transportation ,Electronics ,Construction and electronics, to produce parts with high precision and tight tolerances. The process produces parts with a smooth surface finish and tight dimensional tolerances, reducing the need for additional finishing processes. Metal CNC machining is a reliable, efficient method for producing high-quality metal parts for a variety of applications.

| Product Name | asa plastic 3d printing |

| Brand Name | Wiesel |

| OEM/ODM | Support |

| Place of Origin | Fujian,China |

| Condition | New |

| Application | Agriculture ,Robotics ...etc |

| Export countries | Russia,Mexico,Bolivia...etc |

| Export region | Oceania,Middle East,Southeast Asia,North America... |

| Design | advanced |

| Material Capabilities | Aluminum,Stainless steel,Precious Metals... |

| Type | mold/cnc |

| Loading port | xiamen |

| Warranty | 12 months |

| Color | Customized |

| Surface treatment | Sandblasting,Powder Coating,Color Anodize,Zink Plating... |

| Packaging Details | Carton |

| After sale service | Online support |

| Lead time (days) | 7-30 (To be negotiated) |

Our company information

customized service

Our advantage

The packaging&shipping for asa plastic 3d printing

Xiamen Wiesel technology Co., Ltd mainly provides plastic injection moulding,sheet metal fabrication,gear CNC for plastic/metal,PMMA/PC_CNC,plastic CNC,vacuum casting,stamping mold,die casting mlding,plastic mold,arbor press injection mold, etc., which can be used in Telecommunications ,Aerospace,Musical instruments ,Furniture ,Food and beverage ,Entertainment ,Defense and other industries. It is equipped with advanced software that allows for precise control of cutting tools, resulting in consistent and uniform production. This method provides excellent repeatability, ensuring every part is identical and meets the required specifications.

| Product Name | arbor press injection mold |

| Brand Name | Wiesel |

| OEM/ODM | Support |

| Place of Origin | Xiamen,Fujian |

| Condition | New |

| Application | Education ,Oil and gas ...etc |

| Export countries | Mexico,Canada,Kenya...etc |

| Export region | Southeast Asia,Asia,North America... |

| Design | advanced |

| Material Capabilities | Precious Metals,Aluminum,Steel Alloys... |

| Type | mold/cnc |

| Loading port | xiamen |

| Warranty | 12 months |

| Color | Customized |

| Surface treatment | Zink Plating,Electroplating,Powder Coating,Color Anodize... |

| Packaging Details | Carton |

| After sale service | Online support |

| Lead time (days) | 7-30 (To be negotiated) |

Our company information

customized service

Our advantage

The packaging&shipping for arbor press injection mold

It is a computer numerical control (CNC) machining process that uses rotating tools to remove material from a Magnesium aluminum alloy,Vanadium,Molybdenum,Hastelloy,Stainless steel,Silver,Iron,Manganese workpiece. The process is controlled by a computer program that uses precise measurements and instructions to achieve a high level of accuracy and repeatability.

| Name | apex die casting |

| Material Capabilities | Brass,Steel Alloys,Stainless steel... |

| Type | Laser Machining, Milling, Other Machining Services, Turning, Rapid Prototyping |

| Surface treatment | Zink Plating,Electroplating,Sandblasting,Powder Coating... |

| Tolerance | 0.006-0.01mm |

| Process | Cnc Machining + Surface Treatment |

| Equipment | Milling Machine :3/4/5 Axis CNC Machining Center:Turning Centre |

| Quality Control | ISO/TS9001 |

| Name | Custom Machining Metal Parts Service |

| Place of Origin | Xiamen,China |

Our company information

customized service

Our advantage

The packaging&shipping for apex die casting

It is versatile and can be used to create a variety of parts from simple to complex designs using a variety of metals including Hastelloy,Silicon,Platinum,Brass alloy,Titanium,Manganese,Zinc alloy,Inconel. The precision and consistency of these machines allows for tight tolerances and surface finishes to produce high-quality products and minimize waste.

| Name | apex aluminum die casting |

| Brand Name | Wiesel |

| OEM/ODM | Acceptatble |

| Place of Origin | Fujian,China |

| Condition | New |

| Export region | South America,Oceania,Middle East,Europe... |

| Style | Modern |

| Certificate | ISO9001 |

| Processing Type | CNC milling,CNC boring,CNC lathe machining,CNC grinding,CNC turning... |

| MOQ | 100 Set |

| Warranty | 12 months |

| Color | Customized |

| Packaging Details | Standard |

| After sale service | Online support |

| Lead time (days) | 7-30 (To be negotiated) |

Our company information

customized service

Our advantage

The packaging&shipping for apex aluminum die casting

We provides precise metal processing capabilities for a variety of materials, including Magnesium aluminum alloy,Zinc alloy,Tungsten,Bronze,Copper,Gold,Silver,Beryllium,Chromium. Our state-of-the-art CNC machines utilize computer numerical control technology to ensure consistent, reliable results with tight tolerances and superior surface finish.

| Product Name | aluminum injection mold |

| Brand Name | Wiesel |

| OEM/ODM | Support |

| Place of Origin | Xiamen,Fujian,China |

| Condition | New |

| Application | Oil and gas ,Tooling and machinery ...etc |

| Export countries | Singapore,United States,Peru...etc |

| Export region | Africa,Oceania,South America... |

| Design | advanced |

| Material Capabilities | Steel Alloys,Stainless steel,Brass,Precious Metals... |

| Type | mold/cnc |

| Loading port | xiamen |

| Warranty | 12 months |

| Color | Customized |

| Surface treatment | Sandblasting,Zink Plating,Electroplating,Powder Coating... |

| Packaging Details | Carton |

| After sale service | Online support |

| Lead time (days) | 7-30 (To be negotiated) |

Our company information

customized service

Our advantage

The packaging&shipping for aluminum injection mold

If need more information, please send us message